Monoclonal vs. Monoclonal Antibodies vs.

Antibodies have been used extensively over the past few decades as an extremely powerful and useful tool to detect, quantify, characterize, purify, and purify molecules of interest. Their utility is based on their ability to selectively bind an epitope from carbohydrates, protein or nucleic acids.

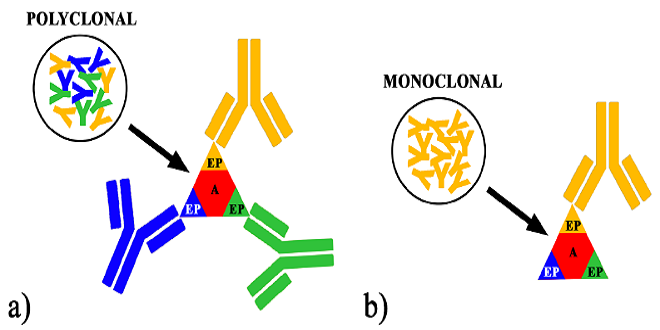

The research uses two types of primary antibodies: monoclonal and polyclonal. Both monoclonal and polyclonal antibodies play an important role in the immune response and can be used to address different research questions. There are many differences in the production methods that have led to monoclonal and multiclonal antibodies having different characteristics.

This article will provide an overview of their production process, distinguishing properties, and roles in research, diagnostics and therapeutics.

Polyclonal Antibodies

Polyclonal antibodies (IgGs) are heterogeneous combinations of immunoglobulins that recognize and bind to multiple epitopes within the same antigen.

A low dose of an antigen (proteins or synthetic peptides), is used to produce polyclonal antibodies. To stimulate the production of antibodies, inject different types of antigens into animals. The animal receives a secondary, or even tertiary booster vaccination of the same antigen after several days to increase the titers.

You can either obtain polyclonal antibodies directly from the serum, or you can purify the solution to remove other serum proteins. This will limit cross-reactivity.

Monoclonal Antibodies

Monoclonal antibodies, which are generated from multiple B-cells within an animal, are produced ex vio using tissue culture techniques. Stable hybrid B cell clones were created from one parent cell, resulting in an identical population of monoclonal antibodies with monovalent affinity that targets a specific epitope of each antigen.

The production process starts with multiple immunizations of the animal with the desired antibody. After several weeks, B-cells from the animal’s spleen are removed and immortalized with hybridoma cell fusion (spleen cells cannot grow in culture). Then the antibody screening is performed.

Hybridomas can be grown continuously in culture and produce antibodies. This allows for unlimited production of monoclonal monoclonal antibodies.

Monoclonal vs. Monoclonal: Advantages & Disadvantages

To choose the right process for your application, it is important to fully understand the limitations and differences of each process. Below is a table that lists the key benefits and drawbacks of each process.

Table 1: Advantages & Disadvantages of monoclonal and polyclonal antibodies

Choosing an Antibody

Monoclonal antibodies’ true potential lies in their monospecificity and homogeneity as well as their consistency. These characteristics strongly suggest their use in clinical settings and affinity purification. Monoclonal antibodies with the desired specificity can be difficult to produce, are expensive and take a lot of time.

Monoclonal antibodies can be used in a variety of ways, including:

Therapeutic drug development

Flow Cytometry

X-ray crystallography

Gene sequencing.

The advantages of polyclonal antibody are often more beneficial than monoclonal ones for general research purposes. Monoclonal antibodies are more difficult to make than polyclonal antibodies. They can be produced much faster, for a lower price, and require less technical skill.

The polyclonal antibody is suitable for many applications including:

Hemagglutination reactions

Immunoprecipitation assays

ELISA, WB, microarray assays, IHC, etc.

IP or ChIP.

Custom Rabbit Polyclonal Antibody Production Service

There are many host species that you can choose from to generate your antibodies. For producing polyclonal antibody, the most common host is rabbit. Because it has more antigen classes than rabbit, and produces the highest yields in the shortest time period, 95% of all the time, rabbit is preferred.

The production of antibodies is complex and requires a high level of technical knowledge. There are many reagents available that can be used to solve problems quickly and reduce costs, but these products may not always meet the needs of specific research projects.

If you are looking for additional security and assurance in your scientific successes, custom rabbit polyclonal antibodies production and development can be a good option.

Boster Bio is a world-renowned antibody manufacturer and offers a cost-effective, reliable, and flexible custom rabbit polyclonal antibody production service. This will help you manage your polyclonal antibodies development project, from antigenic selection through to the delivery of affinity purified antibodies. Boster’s custom-made rabbit polyclonal antibody service platform is capable of producing high-quality custom bunny polyclonal antibodies that can be used in downstream applications.